The tip of a screwdriver was left in the engine of a Jetstar A320 aircraft for over 100 flights before the tip hit the fan, sending flames shooting out of the engine accompanied by loud vibration and popping, aborting the Cairns-bound flight’s take-off from Brisbane Airport.

The tip of a screwdriver was left in the engine of a Jetstar A320 aircraft for over 100 flights before the tip hit the fan, sending flames shooting out of the engine accompanied by loud vibration and popping, aborting the Cairns-bound flight’s take-off from Brisbane Airport.

The dramatic incident, which happened last year, is described by the Australian Transport Safety Bureau (ASTB) in a newly released report.

The screwdriver tip was left inside the engine during maintenance, the ATSB found.

On 23 October 2020, the Jetstar Airways-operated A320 was departing on a scheduled passenger flight from Brisbane to Cairns.

As power was being applied for take-off, the crew felt a vibration and heard a popping noise, which rapidly grew faster and louder. At the same time, the aircraft pulled hard to the right, “diverging to the right of the runway centreline” – despite the first officer applying full left rudder pedal.

The captain immediately activated reverse thrust and brought the aircraft to a stop.

Some of the passengers aboard the aircraft reported seeing flames coming out of the right engine, the ATSB reported. The flames were also sighted by a Brisbane tower air traffic controller and flight crew of a following aircraft.

The A320 taxied back to the airport gate and all passengers and crew disembarked safely.

Engineers then reported finding metallic debris in the tailpipe of the aircraft’s right engine. On disassembly, it was discovered the engine’s high-pressure compressor had sustained significant damage. Most crucially: a removable screwdriver tip was found in the engine’s combustion section.

Incredibly, the ATSB’s investigation determined the screwdriver tip had been in the engine for over 100 flights.

“The ATSB concluded the tool bit had been left in the engine after maintenance and when the engine was running, it entered the high-pressure compressor, leaving dents and nicks in numerous rotor blades and stator vanes,” ATSB Director Transport Safety, Stuart Macleod, stated.

“At least two of these dents and nicks initiated fatigue cracks, which developed during the aircraft’s subsequent operation, and led to a blade failing during the incident flight’s take-off roll.”

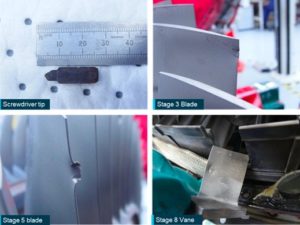

The offending screwdriver tip and some of the damage it caused. Source: Australian Transport Safety Bureau

The separated blade then caused greater damage to the engine’s high-pressure compressor, and the engine surged, triggering loss of power and the low-speed rejected take-off.

Damage to the engine was serious. The ATSB report notes: “Four stage 7 blades and one stage 8 blade were missing and had failed due to overstress. In this section all remaining blades and vanes exhibited hard body damage resulting in severe bending and tearing to both leading and trailing edges. One stage 8 vane contained a distinctive hexagon-shaped dent.”

It didn’t take long to identify what had made that hexagon-shaped dent.

“Small metallic debris and a ¼” hexagon drive screwdriver tool bit (screwdriver tip) was found between the combustion liner and engine case,” the ATSB noted. “The screwdriver tip was burnt/discoloured and the tip eroded due to heat and mechanical damage.”

“Tool control is an important part of maintenance processes,” Macleod commented.

“Small and seemingly insignificant tool components can, and have, caused significant incidents or accidents.”

Macleod said the incident was also a good example of why flight crews need to be aware that the noise and vibration from an actual engine failure may be greater than, or different to, that experienced during simulator training.

“High-fidelity training devices like full motion flight simulators aim to maximise the realism of an artificial environment – but there is a limit to their ability to replicate extreme events.”

Following the incident, Jetstar issued a Safety Alert to its maintenance engineers, emphasising the need for all tooling to be accounted for. The airline also conducted a risk assessment to better understand the on-going risk.

Written by Peter Needham